Corporate museums are part academic and business and occupy the grey zone in between. It is an organization that works with several departments in a company including public relations, branding, advertising, and HR. This series aims to look at the role, function, and future of museums run by corporations through interviews with PR professionals.

The Toyota Commemorative Museum of Industry and Technology—teaching future generations the “spirit of being studious and creative”

Virtual museums are becoming more common these days, but nothing can beat a real experience. That feels especially true when visiting the Toyota Commemorative Museum of Industry and Technology. Its Textile Machinery Pavilion wows visitors with incredible displays that make a point of providing demonstrations and explanations by actual staff. Another highlight is the live demonstrations at the Automobile Pavilion that show parts of the vehicle production process, such as metal working. Here, we take a look at the museum’s appeal to visitors from abroad and the role it plays as a corporate museum.

Motoko Kunita, PR Consulting Dentsu Inc.

Introduction

The Toyota Group currently runs five cultural and exhibition facilities in Japan. Of those five, the Toyota Commemorative Museum of Industry and Technology is the largest in scale, jointly operated by seventeen Toyota Group companies. The museum was built (jointly established by thirteen group companies at the time) in June 1994 to commemorate the 100th anniversary of the birth of Kiichiro Toyoda (1894–1952), eldest son of Toyota Group founder Sakichi Toyoda (1867–1930). It uses the location and buildings that Sakichi initially set up for the research and development of automatic looms in 1911, which later became the main factory for the Toyoda Boshoku Corporation.

The museum is conveniently located, a three-minute walk from Sako Station on the Meitetsu Nagoya Line, the next station from JR Nagoya, or about five minutes by taxi. It is one of the most notable corporate museums in Japan, having had a total of over 6.7 million visitors as of the end of 2022. After a guided tour by Museum Director Kazuhiko Ohora, we interviewed him on the museum’s roles, highlights, and visions for the future.

Overview of the Toyota Commemorative Museum of Industry and Technology

The museum’s concept is to communicate the importance of monozukuri (making things) and the “spirit of being studious and creative” to the next generation. The Toyota Group grew through its business in textile machinery and automobiles, both of which are core industries that supported the development of modern Japan. The museum’s collection of items on display are tremendously significant as resources on Japan’s industrial history.

The location spans roughly 42,000 square meters, upon which stands the historically-important red brick factory building that has been carefully renovated into the museum. The building and a portion of the exhibits were officially recognized as Heritages of Industrial Modernization by the Ministry of Economy, Trade and Industry in 2007. Split into the Textile Machinery Pavilion and the Automobile Pavilion, the museum also houses a restaurant, cafe, museum shop, library, and auditorium in addition to the exhibition areas. There is also an area designed for kids called Technoland, which features original play equipment that incorporate principles and mechanisms used in textile machinery and automobiles, making the museum a fun learning facility for visitors of a wide range of ages.

Exterior of front entrance (source: Toyota Commemorative Museum of Industry and Technology)

The Textile Machinery Pavilion, lined with Sakichi Toyoda’s innovative inventions

From early spinning and weaving tools to modern textile machinery, the Textile Machinery Pavilion features roughly 100 thread and fabric production devices all in one hall. Of the numerous machines on display, the most popular are Sakichi’s very first invention, the Toyoda Wooden Hand Loom (replica human-operated loom) and the Non-stop Shuttle Change Toyoda Automatic Loom (Type G Automatic Loom), which was lauded as the best in the world at the time. The hand loom improved the conventional loom design to allow weaving using one hand instead of two. It also improved quality and weave consistency, and boosted productivity by 40 to 50%. Sakichi developed this loom in 1890, earning him his first patent.

Toyoda Wooden Hand Loom (source: Toyota Commemorative Museum of Industry and Technology)

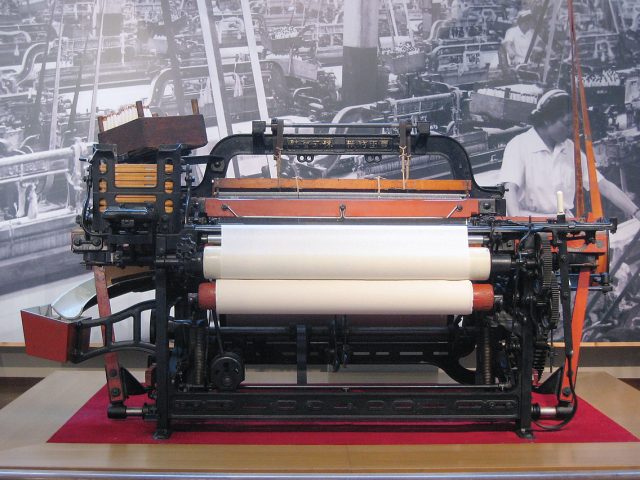

The Type G Automatic Loom completed in 1924 was an innovative machine with many ingenious new features, such as a non-stop automatic shuttle change device that could mechanically change shuttles to replenish weft thread automatically, without compromising high-speed operation. Compared to Sakichi’s previous invention of Japan’s first power loom, the Type G increased productivity by a factor of twenty. The British company Platt Brothers, which was the world leader in textile machinery at the time, was very keen on the new technology and paid to acquire its patent rights. This was a major boost of confidence for the Japanese engineers and provided Toyota the necessary funds to dive into the development and production of Japan-manufactured automobiles.

The Textile Machinery Pavilion makes a point of offering displays with in-person explanations and live demonstrations. Staff are positioned at every major machine, ready to explain to approaching visitors about the mechanism and what sets the machine apart from previous tools, followed by an actual look at the machine in action. That in-person experience and excitement is the pavilion’s greatest appeal, and the museum spares no expense in investing on this feature. A demonstration with the Type G Automatic Loom shows off the shuttle whizzing along at dizzying speed and how the shuttle is exchanged in an instant when it runs out of thread. The demonstration also shows how the machine stops automatically when a warp thread snaps to avoid defects. Even nearly 100 years since its completion, seeing this mechanical feat prompts one to let out an audible “wow.”

Non-stop Shuttle Change Toyoda Automatic Loom (Type G Automatic Loom) (source: Toyota Commemorative Museum of Industry and Technology)

The Automobile Pavilion highlights the challenges and evolution of automobile manufacture

The Automobile Pavilion features the corporation’s history from 1933, when Kiichiro spearheaded the launch of the automobile business, to when they actually started production. It also shows how production technology transitioned and the major car models over the years such as the Crown and Corolla. The history of development during the initial period is explained in particular detail through displays such as a replica of the Materials Testing Center from that time.

Manufacturing automobiles calls for a diverse range of materials, parts, and technological development. Although Toyoda made use of the technology they had amassed from the textile machinery business and studied imported cars for reference, the development of the engine and car body was clearly a difficult road filled with challenges. For example, in 1935 they developed the Toyoda Model G1 Truck (replica on display) in just 9 months by request from the government, but this resulted in much difficulties once it went on sale due to faults found one after another. This, however, led to Toyota’s thorough policies on post-sales services. Elsewhere, Toyota’s first passenger car that came out in 1936, the Toyoda Model AA passenger car (replica on display), is exhibited along with a replicated assembly line from the time, where visitors can see how workers hand stamping metal sheet to create the prototype car body. The Model AA has such a beautiful streamlined design that many visitors mention that they would want to purchase it if it were still sold today.

Metal working and other live demonstrations of the manufacturing process are one of the highlights of the Automobile Pavilion. Visitors can enjoy a re-creation of the hand-forging process from the 1930s, as well as the dynamic forming of steel sheet using the U.S.-made 600-ton press introduced in 1960.

Toyoda Model AA passenger car (source: Toyota Commemorative Museum of Industry and Technology)

A desire to pass on the founding attitudes toward monozukuri

The museum began with a focus on the theme of monozukuri, and did not intially include detailed information on the founders when it first opened. Following its 20th anniversary (2014), the museum decided to tell more stories about the initial period of the business and gradually added sections that introduced the lives of both Sakichi and his son Kiichiro—not to put them on a pedestal, but to let more people, in-company and otherwise, to know that Toyota exists as it is today because of the challenges and hardships that our predecessors overcame.

Although Sakichi was a master inventor, he experienced plenty of setbacks during his lifetime. Kiichiro passed away without getting to see the Toyota automobile business’s first great success with the release of the original Crown in 1955. Kiichiro’s aspirations were passed on to his employees, and they achieved the success that the Toyota Group is today through decades of sweat and determination. The museum also hopes to show the next generation that neither Sakichi nor Kiichiro endeavored for their own sake, but always thought about what they could do for society and the people. They believed that advancing technology and driving industrial development would enrich society, and their philosophy connects to the core foundation of corporations everywhere.

Engine prototyping during the initial period (source: Toyota Commemorative Museum of Industry and Technology)

Beneficial use in internal communication

The fee to enter the museum is at most 500 yen for general admission, which is very reasonable considering all that it offers. This is why most of its operational costs are covered by funds from the seventeen group companies that help run it. The museum’s board of directors is comprised of the presidents from each of the seventeen companies with Toyota Motor Corporation’s Chairman Akio Toyoda, Kiichiro’s grandson, as chairman. Executive officers and general managers from the seventeen companies serve on the operational committee, and meet several times a year to discuss plans and budget considerations. In order to keep functioning as a corporate museum, the museum must convince these companies that it is worth paying for its operational costs, which requires in-depth communication.

The museum is also used for new employee and rank-based training within the Toyota Group. Apparently there are many among new or younger employees who never knew that Toyota had its beginning in the textile machinery industry until they actually start at the company. It’s important for Toyota that employees conduct business with a proper understanding of their predecessors’ attitudes toward monozukuri and the challenges they overcame. Providing such information is a particularly important role the museum plays. In addition, its proximity to Toyota Motor Corporation’s head office means employees and business clients from all over the world visit the museum. Visitors are often amazed by how big the museum is and comment on how they don’t have enough time to see it all. The museum is also popular among people from abroad who are not there for business. Prior to the COVID-19 pandemic, a significant 20% of visitors were from overseas. The museum audio guide is available in six different languages.

A desire to value learning by the younger generation

Branding for Toyota is not a direct goal of the museum. Instead, it aims to be a place of learning that encourages a look at the future from the history of monozukuri. For example, inspiring an interest in the apparel business from seeing how thread is spun and how fabric is woven is just as important a role for a corporate museum to have. That is why the museum values visitors from generations that are high school-aged and younger. During its peak popularity pre-pandemic, the museum had 400,000 visitors a year and a quarter of that, about 100,000 visitors, were high school-aged or younger. The hope is to guide these young visitors to learn and discover the appeal of monozukuri, in order to help them think about their futures.

Constantly providing new draws such as putting on special exhibitions and renewing permanent ones is very important for a museum, and the Toyota Commemorative Museum of Industry and Technology strives to be a place that is worth multiple visits. In order to do so, the museum director himself took online university courses to get qualified as a curator. A few other staff are currently in the process of studying for qualification. Getting qualified while also working at the museum is no easy task, but they aim to have staff who have intimate knowledge of the museum become curators in order to upgrade the way they plan and set up exhibitions.

Many museums attract visitors with their special exhibitions, but since the Toyota Commemorative Museum of Industry and Technology focuses on its permanent exhibitions, they make use of events for any additional information they wish to feature. On the weekends, their incredibly popular monozukuri workshops invite parents and their children to participate. They also hold a special event on the weekend close to the June 11th opening anniversary every year, where they actually run some of the old trucks and passenger cars that are on display. The opening anniversary event is just as popular among adults.

Weekend workshop (source: Toyota Commemorative Museum of Industry and Technology)

The dream is to show what it looks like to start up a business

As a future initiative, the museum hopes to present the specifics of what a startup business looks like. Sakichi and his son Kiichiro were both inventors as well as entrepreneurs, and pioneers in creating the foundations for an entire industry.

Instead of simply showing the history of monozukuri, the museum believes that preserving the journey of creating something from scratch and passing that on to the next generation is just as important. Tackling this theme requires networking with entrepreneurial companies and organizations beyond the Toyota Group, and will be difficult to achieve in the short term. The director explains his hope to pass this vision on to future museum operators so that it might come about someday.

Museum Director Kazuhiko Ohora (source: Toyota Commemorative Museum of Industry and Technology)

In conclusion

In 2021, the museum also set up a virtual guided tour on their official website to allow people to see what the exhibitions are like even when visiting proved difficult due to the pandemic. The virtual tour is very comprehensive and covers a lot of content, but the excitement of seeing the machines operate is best experienced in-person. Museum Director Ohora says that he encourages those who can to actually visit the museum and experience the world of monozukuri for themselves.

We asked what souvenirs from the museum shop were most popular, and apparently miniature cars are particularly popular as many visitors are car afficionados. Food items such as cookies and pre-packaged curry are staple items, but recently some museum-original forks and spoons with a wrench designed on one end have been popular.

Wrench-ended spoons and forks (source: Toyota Commemorative Museum of Industry and Technology)